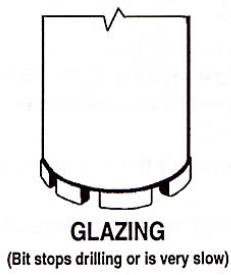

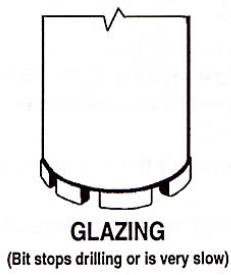

Glazed / Polished Bits - Causes & Remedies

|

|

|

|

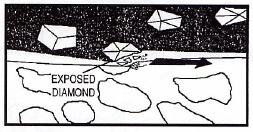

Possible Cause: Too much feed pressure

Remedy: Open the bit with an abrasive material (Such as sand pot,

concrete block, cinder block, etc.)

Possible Cause: Aggregate is too hard. (Example using a bit designed for

soft abrasive material to drill concrete).

Remedy: Use a core drill bit designed with a softer bond.

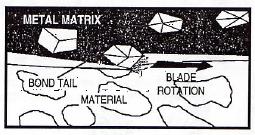

Possible Cause: RPM of core drill is too high for the bit diameter. Surface

speed of the bit rotation is a function of RPM and diameter. A fast rotation

speed is necessary for small bits, but as bits get larger - circumfrence speed

increases relative to π. Too fast and the bit will glaze.

Remedy: Adjust motor speed (if possible), otherwise you will need to

purchase a motor with an appropriate speed.

|

|

|

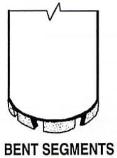

Bent Bits - Causes & Remedies

|

|

|

|

|

Possible Cause: Too much feed pressure & Not enough water

Remedy: Repair the bit (if possible). Ease up on the feed pressure and increase water

flow.

Possible Cause: Aggregate is too hard. (Example using a bit designed for soft abrasive

material to drill concrete).

Remedy: Use a core drill bit designed with a softer bond.

|

|

|

|

|

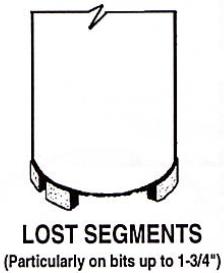

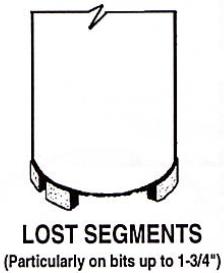

Lost Segments - Causes & Remedies

|

|

|

|

|

|

|

Possible Cause: Steel reinforcing rod

Remedy: Ease up on the feed pressure. Use a higher quality bit and

increase the water flow.

Possible Cause: Not enough water to properly cool bit.

Remedy: Increase water flow.

Possible Cause: Drill rig is not properly anchored.

Remedy: There are three ways of anchoring a core rig. STANDING ON IT IS

NOT ONE OF THEM! This quick and dirty method damages the bit and the

rig as well as dramatically slowing the drilling process.

|

|

|

|

|

|

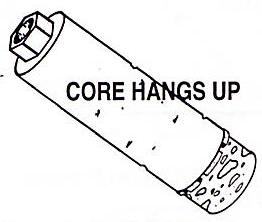

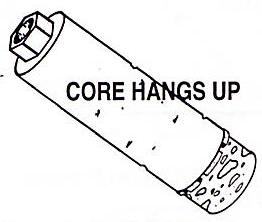

Hung / Stuck Bits - Causes & Remedies

|

|

|

|

|

Possible Cause: Not enough water to remove slurry.

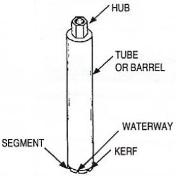

Remedy: Remove bit and drive core out with a spike through the hub.

Increase water flow.

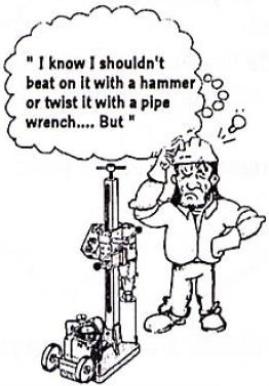

Possible Cause: Core barrel is dented because of hammering on it

to remove previous hung up cores.

Remedy: Repair the barrel (if possible). Increase water flow.

|

|

|

|

|

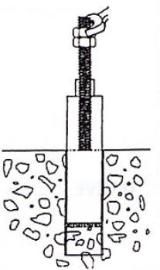

How to Remove a STUCK Bit - Without Damaging it.

|

|

|

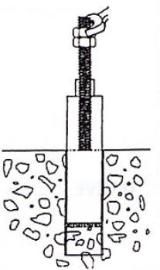

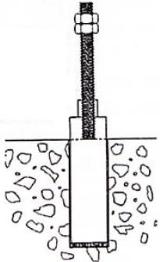

STEP 1: Disconnect

the core rig from the bit.

|

|

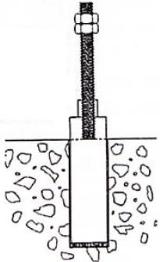

STEP 3: Place two

hex nuts on the rod and

lock them against one

another so that they in

turn lock themselves on

the rod.

|

|

STEP 4: Turn the

nuts with a wrench which

will turn the rod which will

push against the

concrete core, pulling

the bit from the hole

without damaging it.

|

|

|

|

|

|

|

|

STEP 2: Thread a

piece of threaded rod

the same diameter as

the bit (Bit sizes 1.5" and

smaller use 5/8-11

thread and larger bits

use 1-1/4-7 thread).

Thread through the hub

until it hits concrete.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|