- Basic Electricity

- Phase

- Output

- What size do I need?

- Power Quality

Generator Operations

A generator converts mechanical energy into electrical energy. Electricity is commonly described in terms of voltage, amperage and watts.

In an electric circuit, if there is pressure (voltage), and a path provided, then electricity will flow (current) through the conductor. Voltage is the force that causes elecctricity to flow through wires, while current is the movement of electricity.

|

||||

Direct Current

Direct Current (DC) is an electrical charge that flows in one direction through a circuit. It is commonly used in consumer goods such as radios and automobiles. Dry cells and batteries are some other common sources of direct current. A direct current source is marked with plus (+) and minus (-) symbols that indicate the direction of current flow in the circuit. The theory behind direct current holds that it flows from the positive (+) terminal, through the circuit and returns to the negative (-) terminal of the power source. |

Alternating Current

Alternating current (AC) changes its direction of flow at regular intervals and is found in all residential, commercial and industrial applications. Utility companies generate electrical power at several thousand volts and send it hundreds of miles. It is converted to higher and lower values through transformers. |

Frequency

The rate at which alternating current changes direction determines its frequency. Each time the curent goes one way and then the other way is called a cycle. Frequency is the number of cycles that occur in a single time period. Frequency is also commonly referred to as Hertz (Hz) or CPS (cycles per second). One Hz is equal to one CPS. In the Untied States standard houshold current is 60 Hz, while many foreign countries use 50 Hz current. In the construction industry 180Hz "high-cycle" current is used to power certain power certain concrete vibrators (referred to as "High-Cycle Vibrators"). |

Phase:

Phase is a term applied to designate the circuits of an AC system. In the single-phase system, the voltages are in the same time phase in all parts of the system. In the three-phase system, the voltages are 120° apart. |

Single-Phase:

Single-Phase power can be transmitted by either a two-wire circuit or a three-wire circuit. The single-phase two wire method is the simplest and most commonly used. The voltage associated with this method is 120V AC and is used to power lamps, small motors, hand tools and appliances.

|

Three-Phase:

Three-Phase power is transmitted by three hot wires with one ground. It is more versatile than single-phase power and is commonly used in industrial and commercial applications. One reason for this is a three-phase motor is easier to start and more efficient than a single-phase design. It is not used in residential applications. Construction equipment typically uses either single phase or three phase motors. The contractor should specify the phase required for the job. CESSCO carries full-lines of generators that provide both single and three-phase power. |

Continuous Output vs. Maximum Output:

Output references power from the generator Continuous Output: Refers to the total wattage put out by the generator over a long period of time. Frequently refered to as "rated" output, it takes into account the effects of heat on generator efficiency. When sizing a generator, continuous output is more important than... Maximum Output: The total wattage put out by the generator over a short period of time. Once the generator has been running for about 5 minutes the heat created by the machine will lower the electrical output. Starting Amperage vs. Running Amperage:

There is also a difference between starting amperage and running amperage. Starting Amperage is the amount of amps required to start an electric motor when you select a generator the Maximum Amperage should be larger than the Starting Amperage of the equipment you are powering. Running Amperage is the is the amount of amps required to continuously run a motor. Continous Amperage of the generator you select should be larger than the required running amperage of the equipment you are going to power. |

Generator Sizing:

The first thing you will need to do is determine what type of load you will be using with your generator. There are two types of loads: Resistive Load: or Reactive Loads are devices that use a heating element and require the same amount of power to start as they need to run. Examples include:

Inductive: or Capacitive, loads are devices that use an electric motor and require more wattage to start up than for continuous operation. Examples include:

Next determine the voltage, amperage, and wattage of the tools that will be ran off of the generator. With this information you can easily determine the total wattage requirement of the equipment being used. This is accomplished by using the... Power Formula:

Use this formula to determine your needs Volts x Amperage = Watts When sizing a generator, choose a unit that has a continuous output equal to or preferably greater than the total wattage requirement of the equipment. It is often a good idea to provide a little more power than what is actually required. This will give you a little more versatility once your using the generator. You may find the need to run more equipment than you initially expected and will appreciate the extra power. Sizing with the "One - Two - Three" method:

|

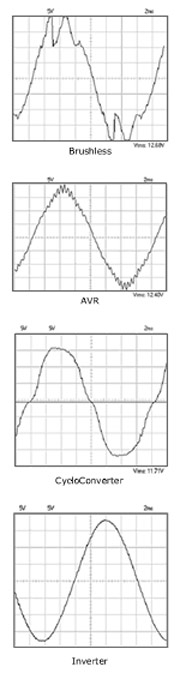

Power Output Quality:

|

|

|

Brushless: Among the most common in the industry because of their inexpensive construction, but have the least reliable voltage control. Brushless generators can't react to a changing load, either producing low power (a brownout) or high power. Fluctuation of this nature can casue equipment damage.

Brushless: Among the most common in the industry because of their inexpensive construction, but have the least reliable voltage control. Brushless generators can't react to a changing load, either producing low power (a brownout) or high power. Fluctuation of this nature can casue equipment damage.  MQ Generator Handbook

MQ Generator Handbook